EBMX XLB-60 Core Motor for E-Ride Pro SS

Product Code MTRV043

£1052.99

FREE DELIVERY

For mainland UK orders over £79.00

Money Back Guarantee

Refunds processed within 30 days

Customer Support

Friendly UK customer support

Secure Online Payment

We possess SSL / Secure Certificate

IMPORTANT:

Compatible with EBMX X-9000 Motor Controller version 2

Description

"In the category of EV Motors and Motor Controllers, EV Motor"

Designed for riders who demand more torque and more freedom, this motor is built to dominate any terrain. Born from the original XLB-60 and sitting alongside the RACE motor, this new edition completes our SurRon and Eride range. The CORE motor has be specifically tuned for dynamic throttle response at lower speeds. But, that does not mean slow!

Rugged Design, Unmatched Agility – Engineered for extreme off-road conditions, agile street riding, and next-level stunt performance.

Precision & Control – Featuring a smoother throttle response for maximum control and confidence.

The EBMX XLB-60 CORE isn’t just a MOTOR—it’s a revolution. This motor gives riders maximum performance at unmatched value.

Suitable for use, with an upgraded battery, in SurRon Light Bee and ERide Pro and more to come!

MTR041 Description EBMX XLB-60 Core Motor Black

The motor in an electric vehicle (EV) is the component that converts electrical energy from the battery into mechanical energy to drive the vehicle. It provides propulsion by generating torque, which turns the rear wheel.

Details

Custom IPM rotor design and industry leading 1mm rotor air gap revving out to rated 13000RPM. Encoder based motor control for increased low end torque response and smooth predicable power delivery.

Encoder sensors, on the other hand, are capable of tracking motor position at all speeds and do so more frequently than hall sensors. As a result they can deliver a smoother more responsive and controllable powerband and they do not generate the same type of current spikes that often cause controller issues. Furthermore, they contribute to improved low-end torque control and overall motor response.

EBMX motor have been custom built and are finely tuned to work with the EBMX X-9000 controller. These motors will work with many other types of controllers, however they may require you to do your own custom tuning.

In contrast to many of our competitors who utilise hall sensors we have opted to incorporate encoder sensors in our motors This decision stems from the fact that encoder sensors demonstrate greater stability under demanding riding conditions While hall sensors rely on estimated rotor positions encoder sensors consistently provide precise angle measurements of the rotors position Hall sensors are typically employed for tracking motor position during startup and up to approximately 2000 rpm after which the motor operates in a sensorless manner However during intense riding situations such as wheel spinning and sudden deceleration combined with rapid throttle adjustments hall sensors angle detection can result in substantial current spikes in the controller This can pose significant issues for many controllers leading to tripping and loss of throttle power although this is less prevalent in the X9000

In contrast to many of our competitors who utilise hall sensors, we have opted to incorporate encoder sensors in our motors. This decision stems from the fact that encoder sensors demonstrate greater stability under demanding riding conditions. While hall sensors rely on estimated rotor positions, encoder sensors consistently provide precise angle measurements of the rotor's position. Hall sensors are typically employed for tracking motor position during start-up and up to approximately 2000 rpm, after which the motor operates in a

In contrast to many of our competitors who utilise hall sensors, we have opted to incorporate encoder sensors in our motors. This decision stems from the fact that encoder sensors demonstrate greater stability under demanding riding conditions. While hall sensors rely on estimated rotor positions, encoder sensors consistently provide precise angle measurements of the rotor's position. Hall sensors are typically employed for tracking motor position during start-up and up to approximately 2000 rpm, after which the motor operates in a

IMPORTANT INFORMATION

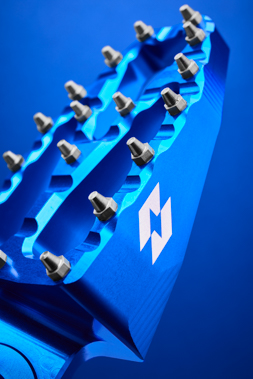

A custom EBMX Bash Plate is included with your motor.

Specifications

WRLM324 Description EBMX XLB-60 Harness and Fitting Kit for PRO-SS

A motorcycle wiring loom, also known as a wiring harness, is a bundle of wires and connectors that transmits electrical power and signals throughout the motorcycle. It organizes and protects the electrical wiring, ensuring connections between components such as the ignition system, lighting, and various sensors. The loom is typically wrapped in protective sheathing to guard against wear and damage, and is designed to streamline installation and maintain a neat, efficient electrical system.

Specifications

Attributes

Compatibility

| Manufacturer | Model |

|---|---|

| E Ride Pro | PRO-SS |